- 864-288-3900

- blaffler@rprinc.com

- 34 Pelham Davis Cr, Greenville, SC

Returnable Packaging Resource is proudly partnered with an industry leading solution in saving space and cost, ITB Packaging. Save up to 45% per part with their advanced designs that make streamlining your supply chain easier, cheaper, and more efficient.

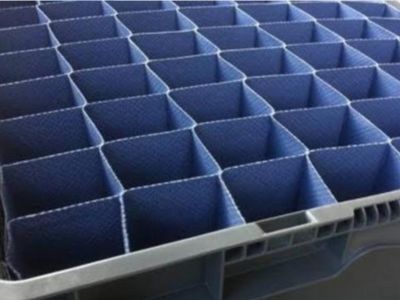

PCOOR Divider:

RPR “In the Box” Divider:

2×5 = 10 parts

48x45x40

2×15 = 30 parts

48x45x40

RPR integrates returnable packaging for large parts and smaller loads, giving you high return ratios with lower shipping costs.

RPR bags and pouches protect the form and value of your products in transit.

We use a range of internal protective packaging technologies for Class A protection. We design our protective dunnage for direct loading into containers.

We fabricate sleeve systems with nestable pallets and tops for 10-year service life, more efficient warehousing, and lower return freight costs.

We engineer turnkeycollapsible, stackable racks, carts, and dollies with and without casters.

We engineer customized thermoplastic trays to protect your high-value parts, machinery, and prototypes in transit.

RPR provides services for some of the world’s biggest brands, including major automotive OEMs along with their Multiple Tier vendors.

RPR is the leading single-source provider of returnable packaging systems and engineering in the Southeastern US.

© 2025 Returnable Packaging Resource